Description

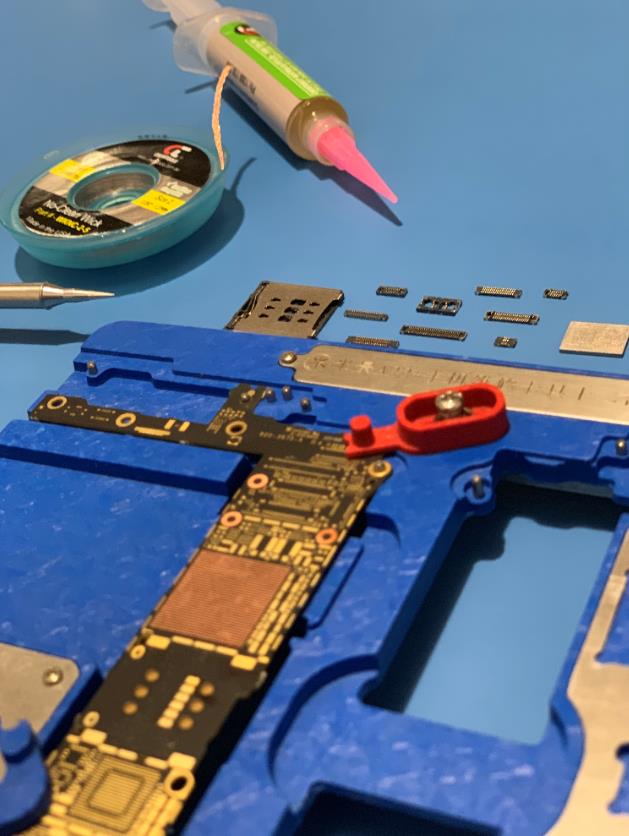

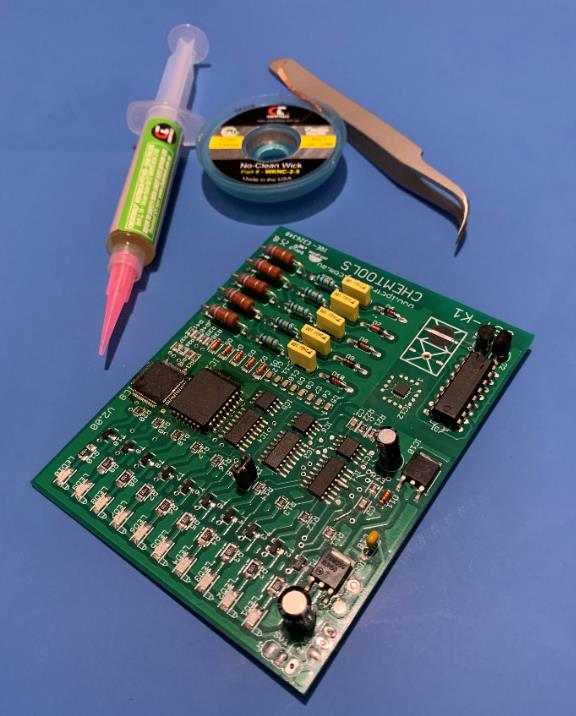

This course teaches students micro soldering skills to repair common logic board issues including charge ports, FPC connectors and more. This is a hands on, practical course where students work on current devices with the latest soldering equipment. Our fully equipment training centre includes, Hot air rework systems, Preheaters, Infrared rework system, Induction heating soldering irons, microscopes and we introduce you to leaded and lead free soldering techniques & many soldering consumable aids used by major electronics service centres across Australia.

We encourage Students to bring some of their own faulty mobile devices requiring soldering repairs to fix during the class.

Students should have some prior understandings on troubleshooting mobile devices, but do not need any previous soldering experience as we begin by teaching the fundamentals of soldering, education on soldering equipment and techniques on Day 1 and then progress into micro soldering on Day 2.

Students will also learn how to address other common issues such as ESD, cleaning and liquid damage.

This course focuses more on the hands on skills for students to learn how to micro solder and which soldering consumables should be used in order to perform successful Class 2/3 solder joints as per IPC standards.

This course is great for repair centres that are currently outsourcing logic board level repairs and want to further expand their in-house capabilities and learn to solder and fix the most common soldering jobs seen in repair centres.

Reviews

There are no reviews yet.